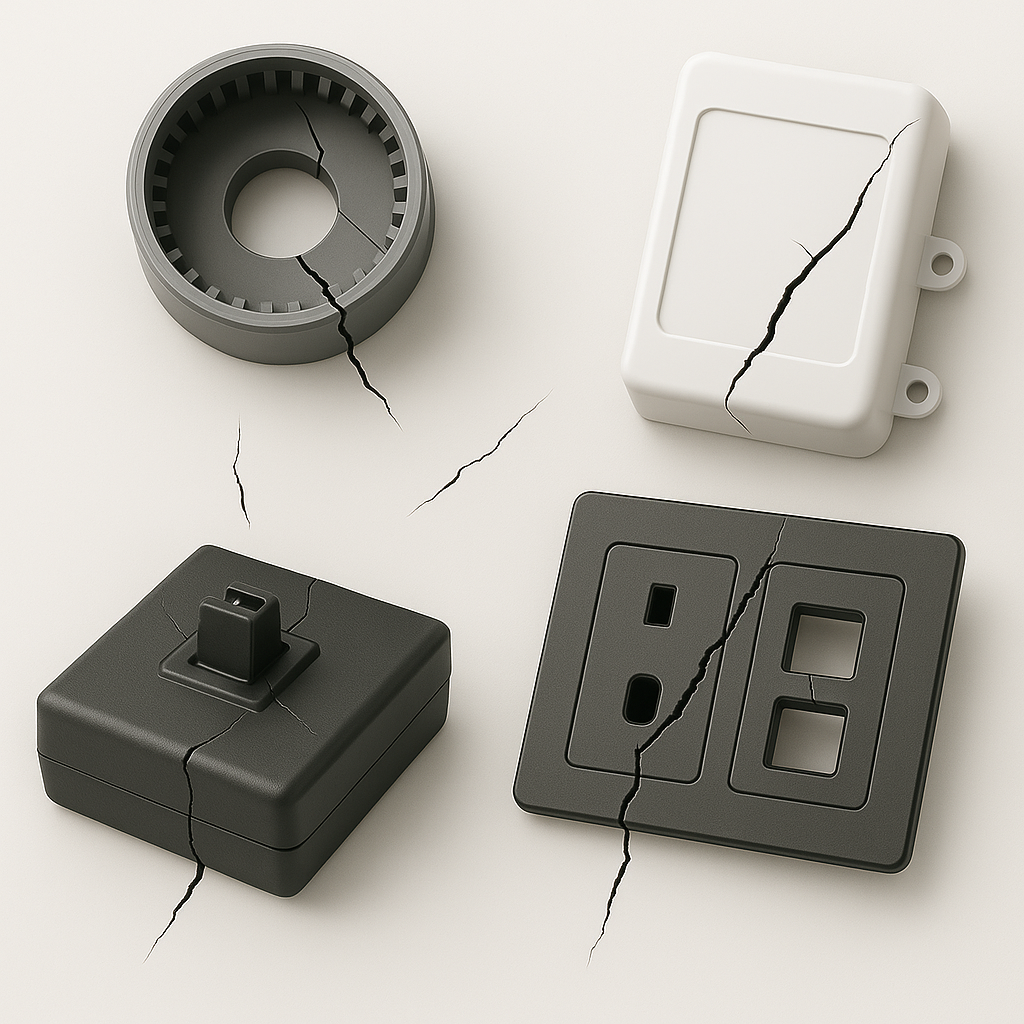

If your parts aren’t filling the mold, leaving voids or short shots, don’t blame the mold or the machine just yet. In many cases, the root cause is poor flow behavior from the compound itself.

Common Complaints From Customers:

“Even after adjusting the injection pressure and temperature, our part still won’t fill.”

This is often a material flow issue, especially in thin-wall designs or multi-gate molds.

What Is Happening:

Low MFR (Melt Flow Rate): The material is too viscous

Excessive filler content (e.g., high GF) that restricts flow

Mold has long flow paths or sharp turns

Processing temperature adjustments have a limited effect

What Samland Offers:

We custom-blend materials to address flow issues at their root cause. No guessing — just data-backed formulations.

Our Solutions Include:

High MFR grades (PA, PC, ABS, PP, etc.)

Flow-modified compounds with lubricants or low-viscosity carriers

Balanced GF loadings to ensure flowability and dimensional integrity

High-flow + low-warp dual optimization

Tips:

For thin walls or long flow paths → Use MFR ≥ 20g/10min grades

For parts with ribs, bosses → Choose lubricated, high-toughness blends

For flow issues + strict appearance standards → Try anti-flash flow modifiers

Need better flow? Samland has you covered. Get in touch for a formula match or sample today.