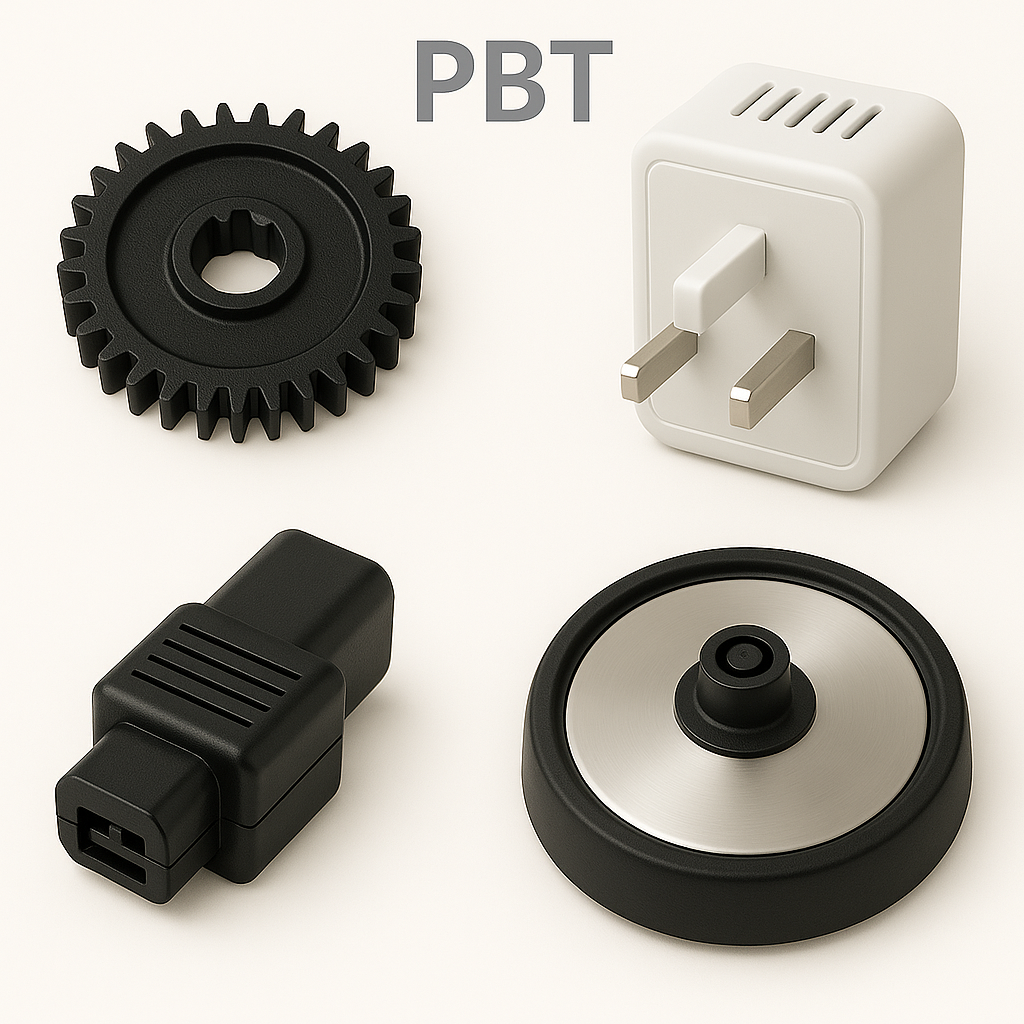

Typical Applications

Our custom PA6, PA66, PC, ABS, PBT, and PP compounds are engineered for use in injection molding and extrusion, featuring optimized MFI, tensile strength, flexural strength, and impact resistance. Available in flame-retardant, glass fiber-reinforced, and high-flow formulations.

Worldwide Clients

Completed Projects

568