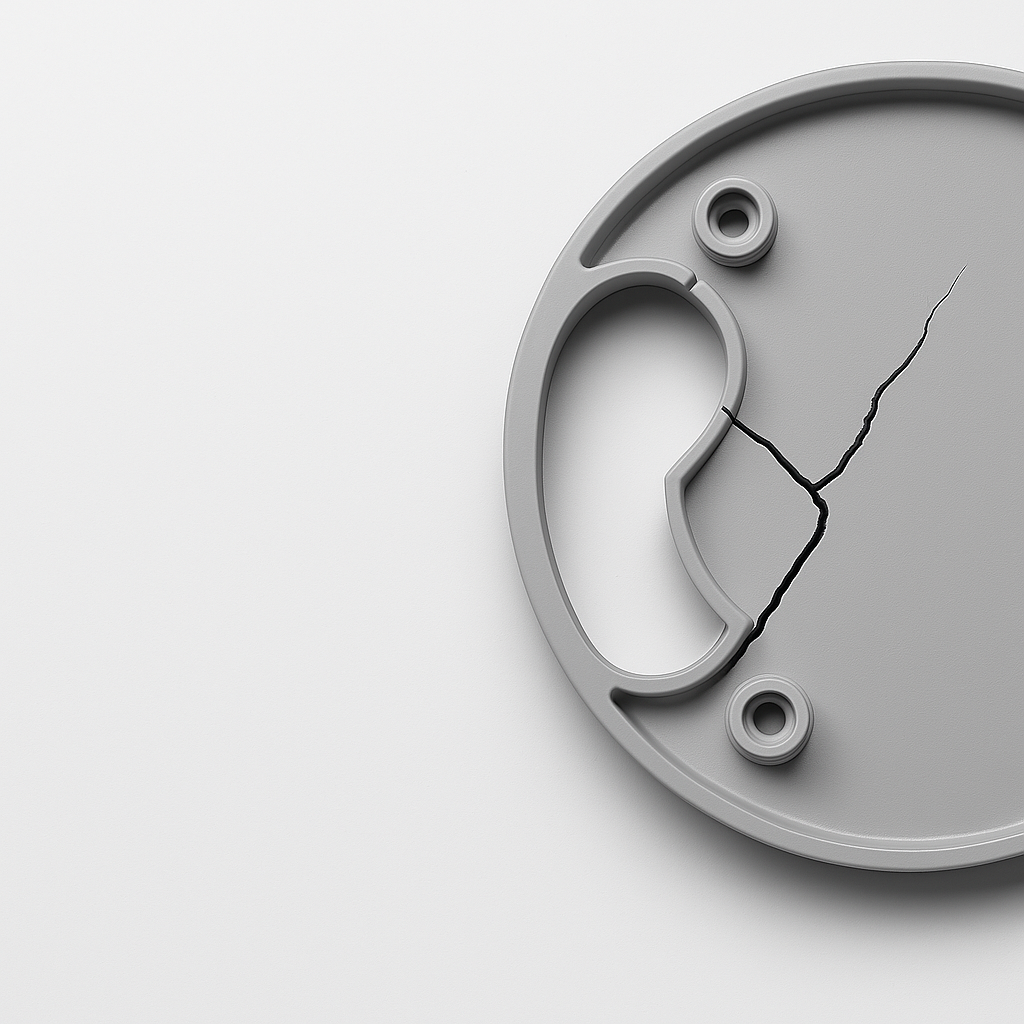

If your plastic parts keep cracking during use, storage, or even shipping, you’re not alone. Stress cracking is one of the most common and frustrating failures engineers and manufacturers face. Let’s break down why it happens and how you can stop it before it costs you more time and money.

The Customer Pain Point

“We used a standard grade. It looked fine after molding. But a week later, cracks appeared around screw holes.”

This scenario is all too common. And unfortunately, standard materials don’t always account for hidden stress. If you’re seeing cracking near fasteners, sharp corners, or load-bearing zones, your part is likely under residual stress, and the material can’t take it.

What Is Stress Cracking?

Stress cracking (also called Environmental Stress Cracking, ESC) occurs when plastic degrades due to a combination of:

Mechanical stress (from molding or use)

Chemical exposure (cleaners, oils, vapors)

Temperature changes (expansion/contraction)

Even if each factor is below the breaking point on its own, they combine over time to create brittle failure.

Common Causes:

Sharp corners or unrelieved ribs in the part design

Fastener stress or press-fit zones

Mold stress (over-packing, cooling imbalance)

Improper material selection for chemical exposure or impact loads

What Samland Can Do

At Samland, we engineer materials specifically to resist stress cracking. If you’re seeing cracking, we’ll help diagnose it and offer compound-level solutions:

We offer:

Impact-modified PA, ABS, and PC for shock absorption

Glass fiber–balanced PA66/PA6 for dimensional stability

Chemical-resistant blends (PC/PBT, PA/PPS, PPA) for ESC-prone environments

Lubricated or flow-enhanced grades to reduce mold-induced stress

All grades are custom-formulated based on your mold design, processing conditions, and product lifespan expectations.

Tips to Avoid Stress Cracking:

Use radius instead of sharp corners

Avoid over-torqued fasteners or tight press fits

Select a compound with proven impact & chemical resistance

Request mold-flow simulation or stress testing support before scaling

We’re Your Materials Partner:

Don’t wait for cracks to ruin your production. If you’re unsure which compound can handle your design or conditions, Samland can formulate and validate it for you—— fast.